1. Distribution box/fire box frame is formed at one time, which can be directly folded into frame structure and controlled by PLC. Multiple safety protection is set up in normal production.

我公司是专业生产配电箱流水线设备厂家,配电箱流水线设备操作系统为全自动智能程序操作控制系统,整条流水线只需一个工人操作即可替代传统工艺生产配电箱10个工人的工作量,既降低了配电箱的生产成本,又提高了配电箱的的生产质量,为企业在现代化市场经济的浪潮中奠定基石。传统工艺生产配电箱,厂家都是使用板料生产箱体,这样就会造成对于成品板料计算不到位,造成板料的浪费,就算是使用激光切割也会有料边浪费情况出现,而且生产效率提升不上去,造成传统工艺生产配电箱难以做大做强。即使做大了企业的用工成本,管理成本成倍增加,造成难管理,没利润的情况出现。

Our company is a professional manufacturer of distribution box pipelining equipment. The operation system of distribution box pipelining equipment is an automatic intelligent program operation control system. The whole pipelining can replace the workload of 10 workers in traditional production process. It not only reduces the production cost of distribution box, but also improves the production quality of distribution box. It is a modern City for enterprises. The foundation stone is laid in the wave of market economy. Distribution boxes manufactured by traditional technology are made of sheet metal, which will result in inadequate calculation of finished sheet metal and waste of sheet metal. Even if laser cutting is used, there will be waste of material edge, and the production efficiency can not be improved, which makes it difficult to make distribution boxes manufactured by traditional technology bigger and stronger. Even if the employing cost of a larger enterprise is enlarged, the management cost doubles, resulting in difficult management and no profit.

山东炜桦智能科技有限公司设计研发生产的全自动配电箱一次成型生产设备,操作简单,使用高效。整条流水线只需一个工人操作,每小时即可生产配电箱100-500个,流水线操作系统采用智能化操作程序。一键式更换箱体生产种类,生产原材料采用带钢生产,不会出现板料料边浪费严重的问题,使用设备生产即提高了生产效率,有节约了原材料,使企业更具有市场竞争力

Shandong Weihua Intelligent Technology Co., Ltd. designed and manufactured a fully automatic distribution box shaping production equipment, simple operation, efficient use. The whole pipeline needs only one worker to operate, and can produce 100-500 distribution boxes per hour. The pipeline operating system adopts intelligent operation procedures. One-button replacement of box production types, production of raw materials using strip steel production, will not appear serious waste of sheet material edge, the use of equipment production is to improve production efficiency, save raw materials, so that enterprises have more market competitiveness.

配电箱自动生产线有以下几个优点:

The distribution box automatic production line has the following advantages:

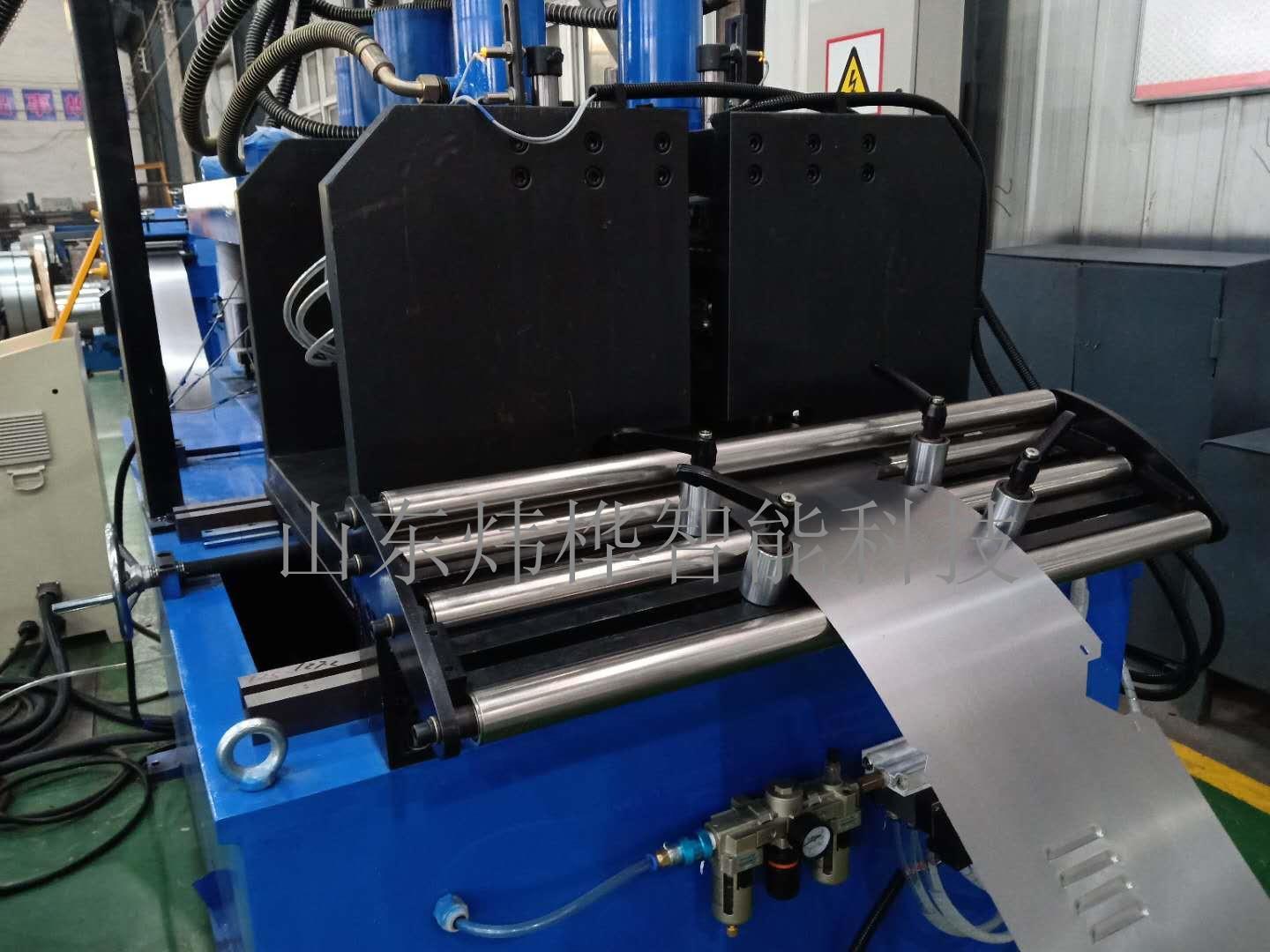

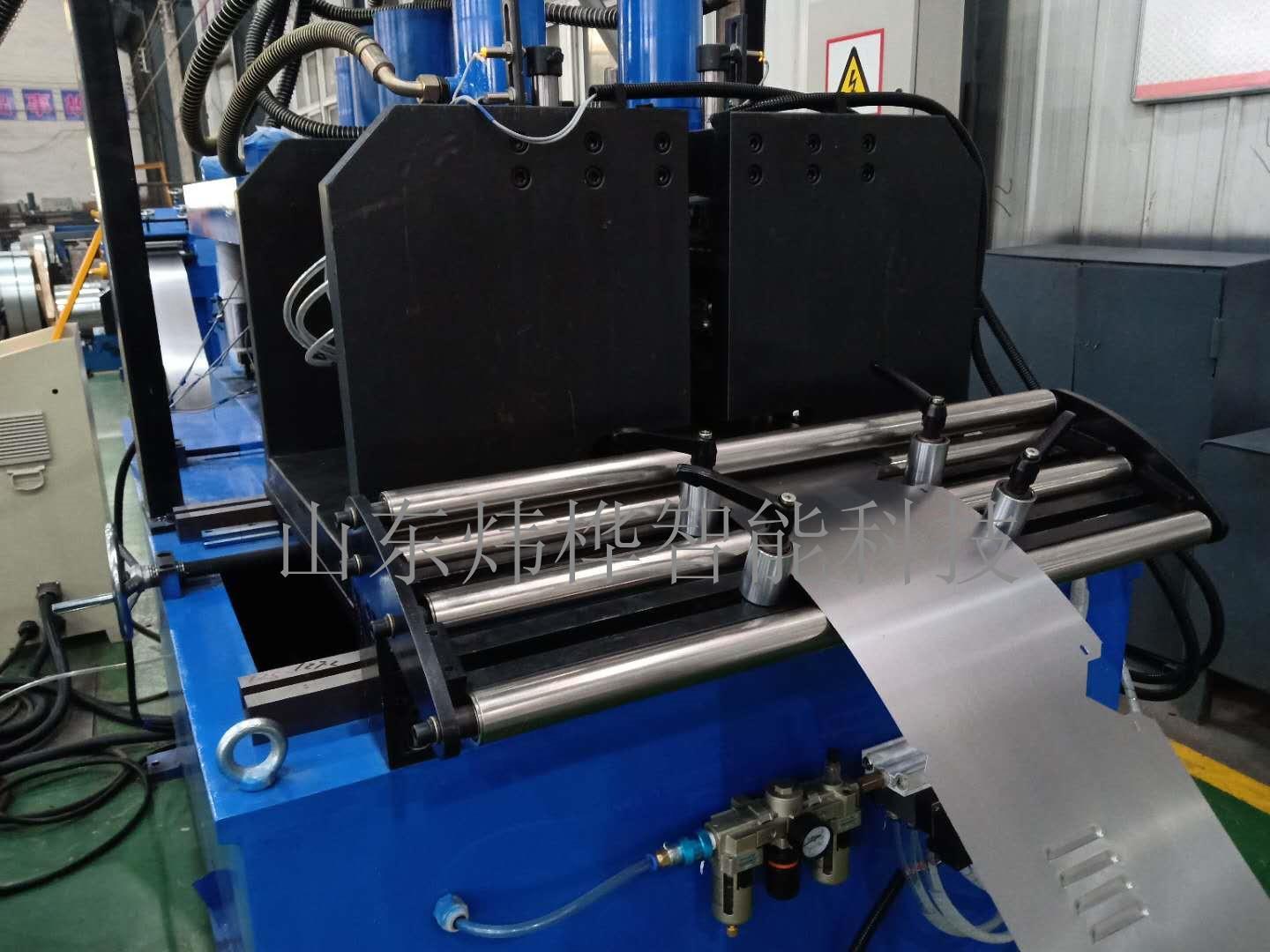

1.配电箱/消防箱框体一次性成型,直接可对折成框体结构电气控制为PLC控制,在正常生产时设制多重安全保护。

1. Distribution box/fire box frame is formed at one time, which can be directly folded into frame structure and controlled by PLC. Multiple safety protection is set up in normal production.

3.床身为钢板焊接件。并作回火处理,消除内应力、避免机身的变形。

3. The bed is welded with steel plate. The internal stress is eliminated and the deformation of the fuselage is avoided by tempering treatment.

4.成型机架为铸铁结构,并经回火处理。强性高,使用寿命长。

4. The forming frame is made of cast iron and tempered. High strength and long service life.

5.轧辊轴的材料为40Cr,并经调质处理,硬度为HB280。

5. The material of the roll shaft is 40Cr and its hardness is HB280 after quenching and tempering.

6.成型模具的材料为GCr15, 淬火处理,硬度:HRC56-62℃。

6. The material of the forming die is GCr15, quenching treatment, hardness: HRC56-62 C.

7.传动结构为齿轮传动。可保证设备**时间,高强度运行,并且使用寿命长。

7. The transmission structure is gear transmission. It can ensure the equipment to run over time, with high strength and long service life.

8.我公司完善设计一整套消防栓箱,灭火器箱,基业箱,明装箱,暗装箱,PZ30,多媒体箱型材成型设备。

8. Our company has perfectly designed a complete set of fire hydrant box, fire extinguisher box, base box, open box, concealed box, PZ30, multimedia box profile forming equipment.

9.在消防箱/配电箱壳体成型方面:成功设计调试生产出单面框体成型机,双面框体成型机,四面框体一次自动 成 型框体机。

9. In the shaping of fire box/distribution box shell, we have successfully designed, debugged and produced one-sided frame shaping machine, two-sided frame shaping machine and one-time automatic frame shaping machine for four-sided frame.

10..根据要求采用多种方式,可一次性完成整体消防箱或配电箱类壳体的自动化生产。

10. According to the requirement, the automatic production of the whole fire box or the shell of the distribution box can be completed in one time by various ways.

配电箱生产设备主要参数

Main parameters of distribution box production equipment

操作系统:触摸屏

Operating System: Touch Screen

重 量:20T

Weight: 20T

控制方式:PLC

Control mode: PLC

操作系统:触摸屏

Operating System: Touch Screen

控制方式:PLC

Control mode: PLC

传动模式:齿轮箱

Drive mode: gearbox

材料规格:Q235

Material Specification: Q235

生产速度:0-15m

Production speed: 0-15m

切断方式:液压切断

Cut-off mode: hydraulic cut-off

电压参数:380V/415V,50Hz, 3相

Voltage parameters: 380V/415V, 50Hz, 3-phase

电气控制:PLC

Electrical control: PLC

潍坊炜桦冷弯机械制造有限公司(简称为“炜桦冷弯”)成立于2004年,位于世界*的风筝之都--山东潍坊,是集设备制造、模具加工、技术开发于一体的综合性机械制造高科技民营企业,已成为建设部金属结构协会会员单位。2010年,公司与山东科技职业学院展开校企合作,委托学校为我公司培养了一大批技术熟练的产业工人,同时学校强大的科研队伍**了我公司产品的高质量水准。2012年在江苏省苏州市(常熟)设立办事处,主要针对南方市场销售和售后服务。2018年,公司为开拓国外市场,成立山东炜桦智能科技有限公司,2018年同年成立山东临沂办事处,主要针对山东南部及苏北客户市场销售和设备售后。2019年成立浙江温州代理分公司,对长江以南的南方市场针对销售及售后服务。炜桦冷弯致力于高精度冷弯型钢及各种非标型材结构研究、设计、生产。是内外贸易一体的高度自动化机械制造型企业。

生产速度:0-6 m/min

切断方式:液压切断

电压参数:380V/415V,50Hz, 3相

电气控制:PLC

驱动电机:变频电机驱动

钢带厚度:2.5mm

钢带宽度:≤120mm,

轧辊材质:GCr15 淬火HRC58°-62°

液压油型号:46#液压油

齿轮油型号:18#齿轮油

总电机功率:27kw

料规格:Q235

3. The bed is welded with steel plate. The internal stress is eliminated and the deformation of the fuselage is avoided by tempering treatment.

http://weifangweihua.b2b168.com