消火栓箱自动生产线技术参数:

开卷:被动上料架

放料架承重:5T

机架:采用方管焊接

中板厚:18mm

成型机导向进料架形式:侧向滚轮式

成型机形式:墙板式链传动

传动方式:齿轮箱

成型机线速度:7-10m/min

成型机道数:七辊校平16道成型。

轧辊材料:轴承钢

轧辊热处理:HRC58°-60

液压站电机:5.5KW

液压站油泵:齿轮泵

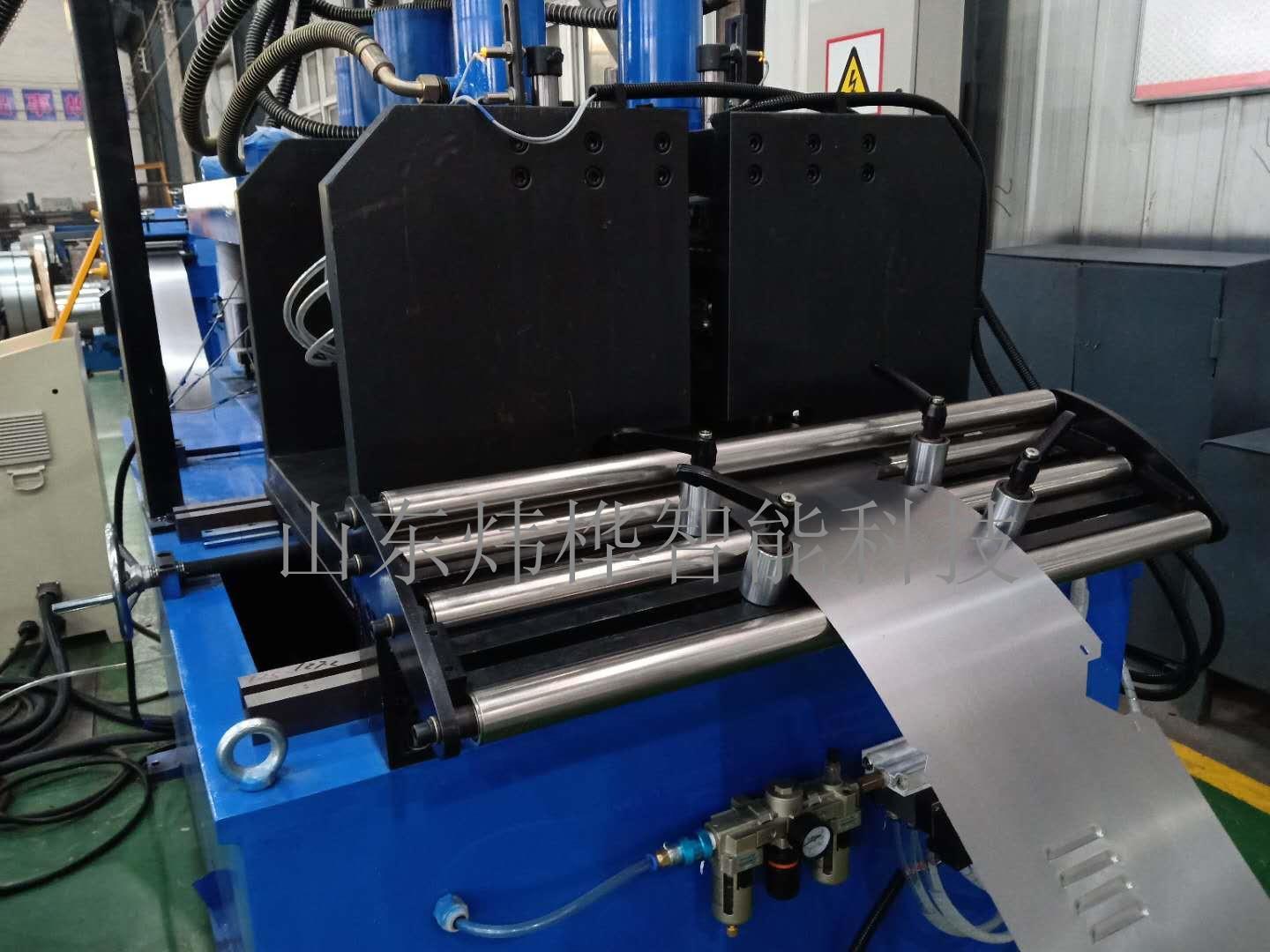

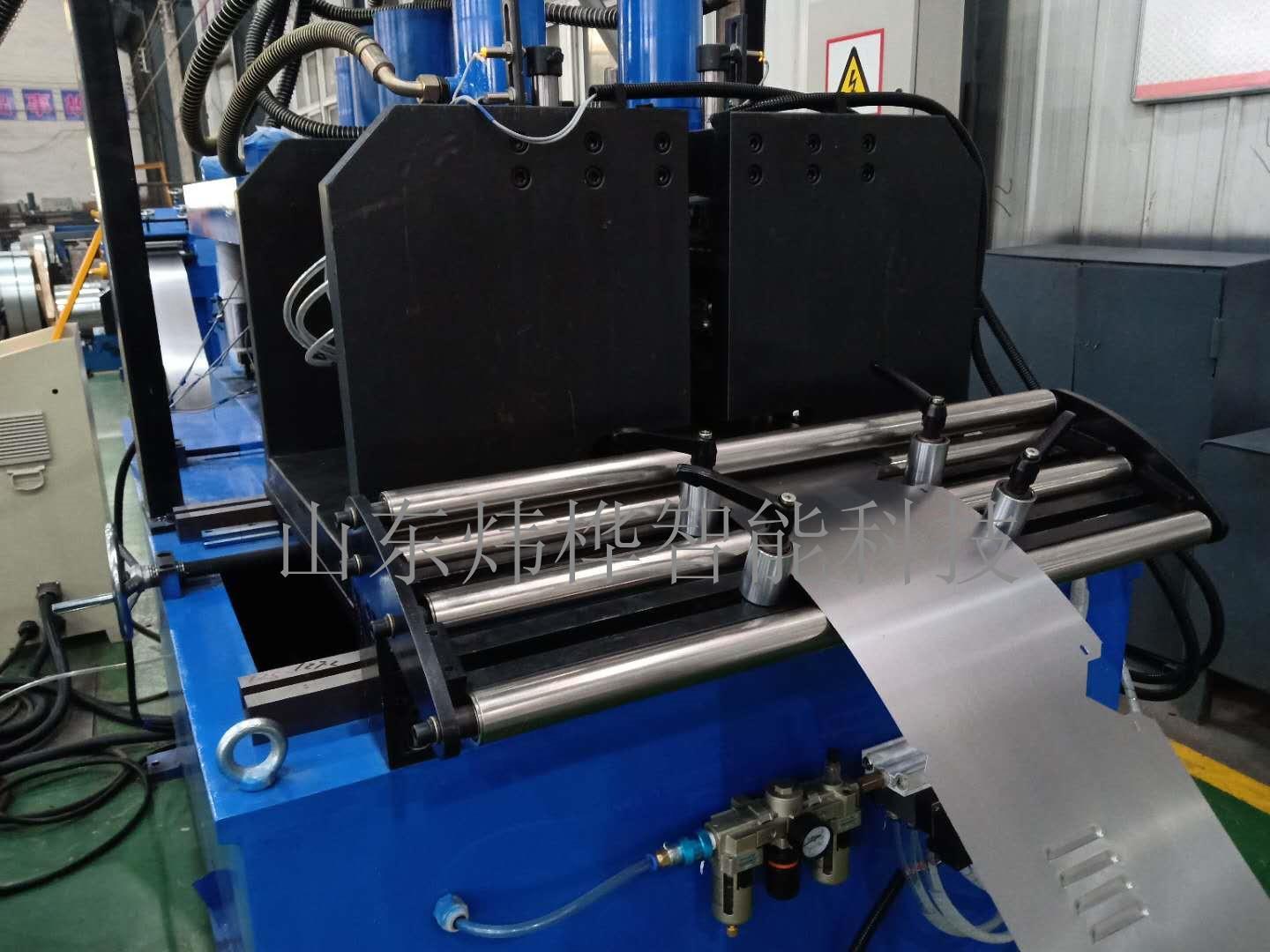

切断方式:无极切断,*更换切刀磨具

轧制厚度:1.0-3.0mm

设备结构及系统配置:

Equipment structure and system configuration:

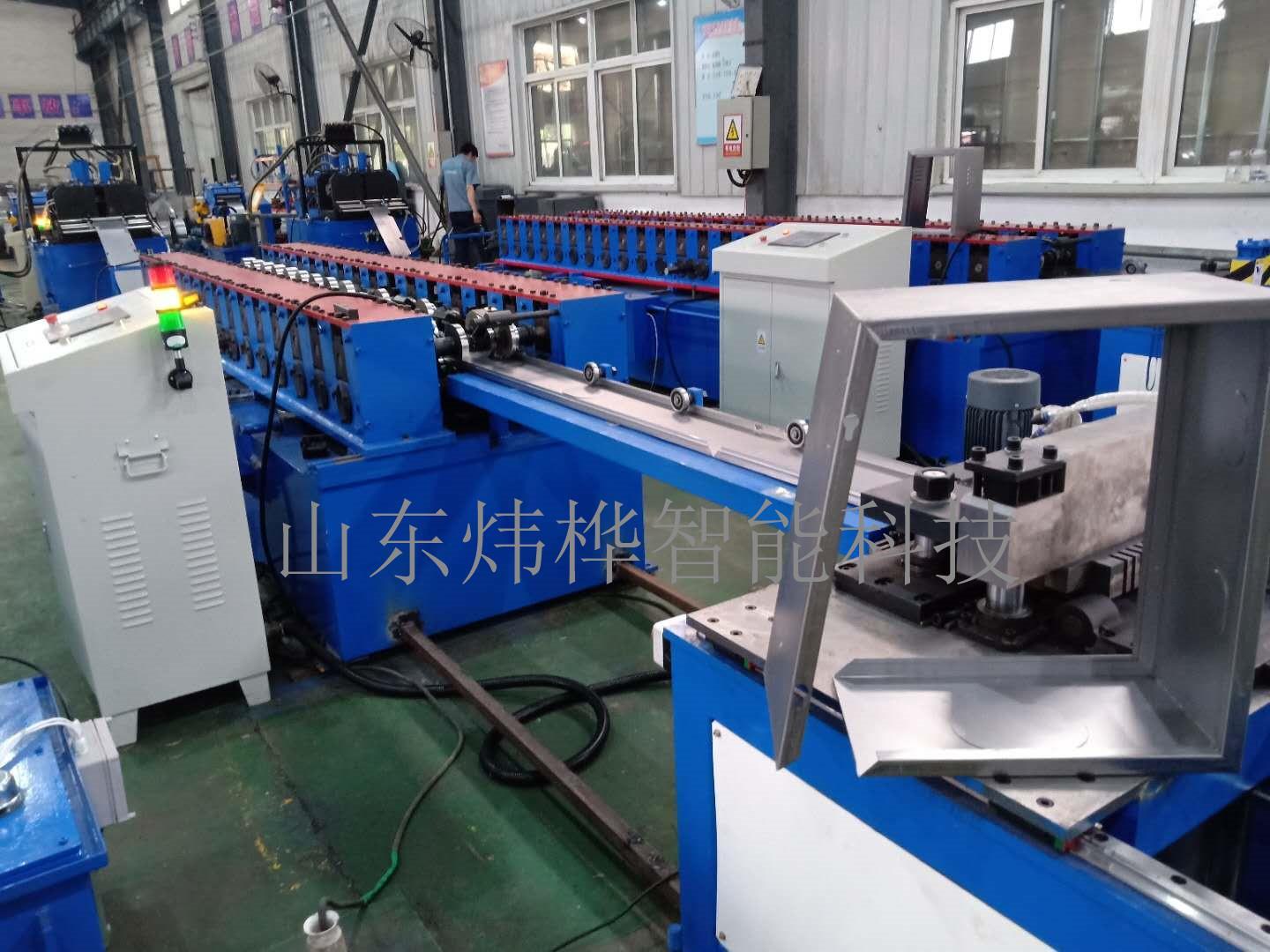

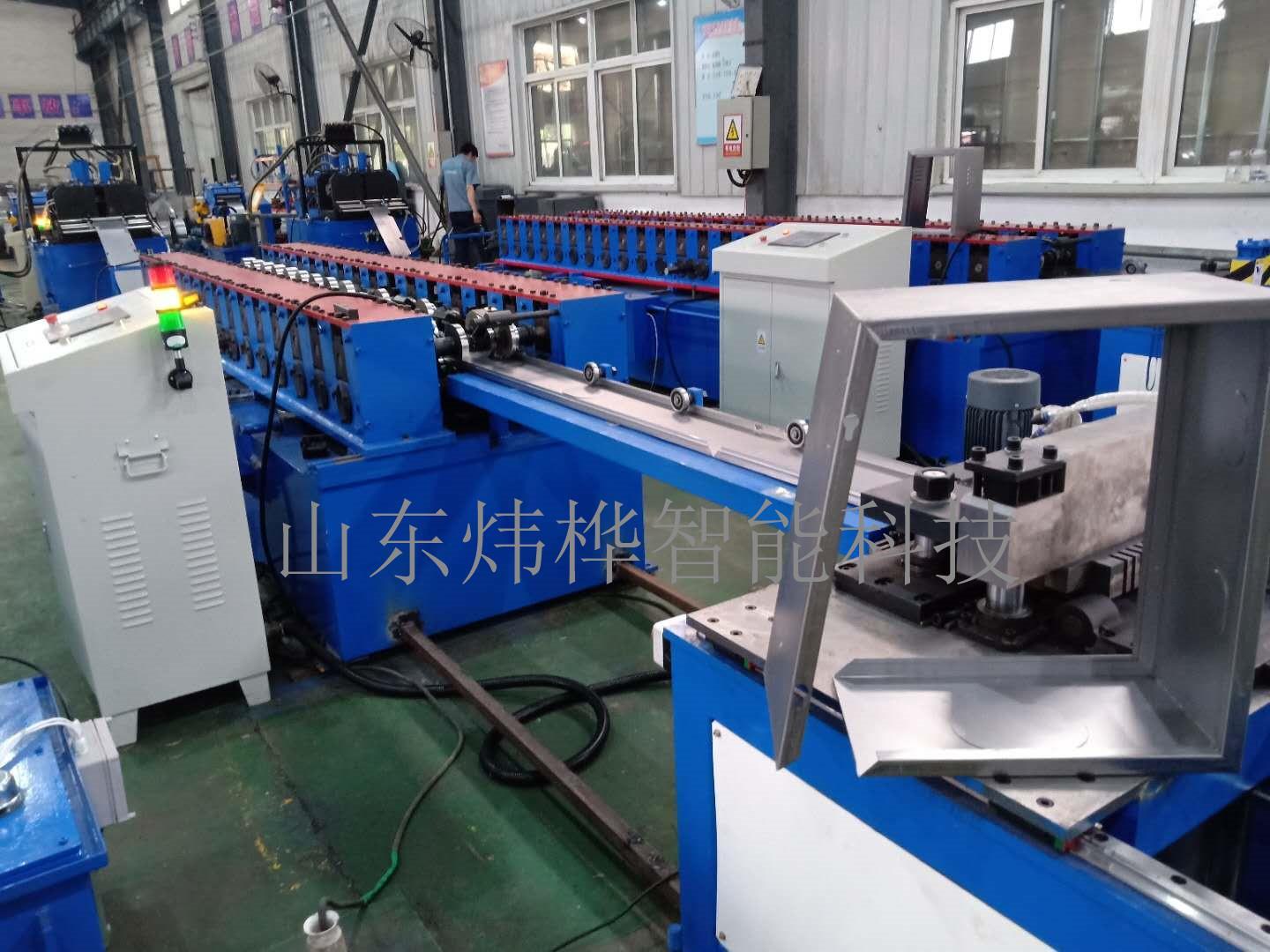

概述:该生产线主要由放料机、调平机、冲孔切断机、输送台、成型主机、液压折边机、成品托料装置、液压系统、电气控制部分及安全防护部分组成。

Overview: The production line is mainly composed of feeder, leveler, punch cutter, conveyor, forming machine, hydraulic folding machine, finished product supporting device, hydraulic system, electrical control part and safety protection part.

1.放料机:用于存入放卷料并给成形部分提供板料,5吨电动放料机液压张紧。

1. Feeder: Used for storing coil and supplying sheet metal to forming part, hydraulic tension of 5 ton electric feeder.

2.整平机:9辊精密整平(上4下5),2.2KW电动送料,用于卷料平直并消除材料应力。

2. Leveling machine: 9 rolls precision leveling (top 4 down 5), 2.2KW electric feeding, used for coiling straightening and eliminating material stress.

3.伺服送料机:含2KW伺服系统,精密送料器,冲孔装置(模具)和切断装置。

3. Servo feeder: including 2KW servo system, precision feeder, punching device (die) and cutting device.

2.成型主机:此生产线的主机机座采用100*100*3MM方钢焊接,机架采用整体式固定牌坊,侧板采用30mm钢板,支承部分均采用优质闽台轴承,进料采用滚轮式,出料采用扭动上下调节,主机钢性好,且结构稳定。

2. Forming machine: The main frame of this production line is welded with 100*100*3MM square steel, the frame is fixed with integral archway, the side plate is made of 30mm steel plate, the supporting part is made of high-quality Taiwanese bearings, the feeding part is rolled, the feeding part is adjusted up and down by torsion, and the main frame is good in steel and stable in structure.

成型参数

Molding parameters

a、 成型组数:16组辊轮成型

A. Forming group: 16 sets of rollers forming

b、 主轴规格:?48mm 45#钢材料调质处理

B. Spindle specification:? 48mm 45# steel material tempering treatment

c、 辊轮材质:Gr12模具钢热处理

C. Roller Material: Heat Treatment of Gr12 Die Steel

d、 整体式牌坊:由25mm钢板精加工而成,孔距误差小于0.1mm

D. Integral archway: made of 25 mm steel plate, with hole spacing error less than 0.1 mm

e、 底板厚度:20mm

E. Floor thickness: 20mm

4、成型能力

4. Forming ability

a. 带卷外径: Φ1250mm(Max.)

A. Outer diameter of tape coil: 1250mm (Max.)

b. 材料成型厚度:0.4-1.0mm

B. Material forming thickness: 0.4-1.0mm

c. 产品宽度100mm-400mm可调

C. The width of the product is adjustable from 100mm to 400mm.

5、成型机组速度参数

5. Speed parameters of forming unit

a. 线速度 0-13m/min

A. Linear velocity 0-13m/min

b. 加速时间 <30秒

B. Acceleration time less than 30 seconds

2.整平机:9辊精密整平(上4下5),2.2KW电动送料,用于卷料平直并消除材料应力。

消火栓箱生产工艺流程:

被动开卷→ 校平→送料→冲压→导向进料→辊压成型→数控折弯→定尺切断→托料出板

http://weifangweihua.b2b168.com